From the Resene paint and decorating problem solver

Resene has created this guide of how to test paints in the field. For technical assistance please use our Ask a Paint Expert Service.

The following test methods are used to help establish/provide basic information, which can be useful in determining the current condition of the applied paint system and also help with advice for preparation and painting.

Use caution with regard to your safety when using sharp knives and solvents and also use caution in determining the results gained from the actual testing, as it is only a basic guide.

Experience will enable you to differentiate between a light or heavily chalked surface.

Alkyd or epoxy based paint coatings subject to exterior exposure are highly likely to give a positive test for chalking.

If no residue removed (seen on the cloth) then it is Colour Fade.Wear safety glasses and gloves.

Clean test area by using Test 3 procedure – Cleaning Surface. Check for surface chalk using Test 2, if positive then clean until a negative result is achieved.

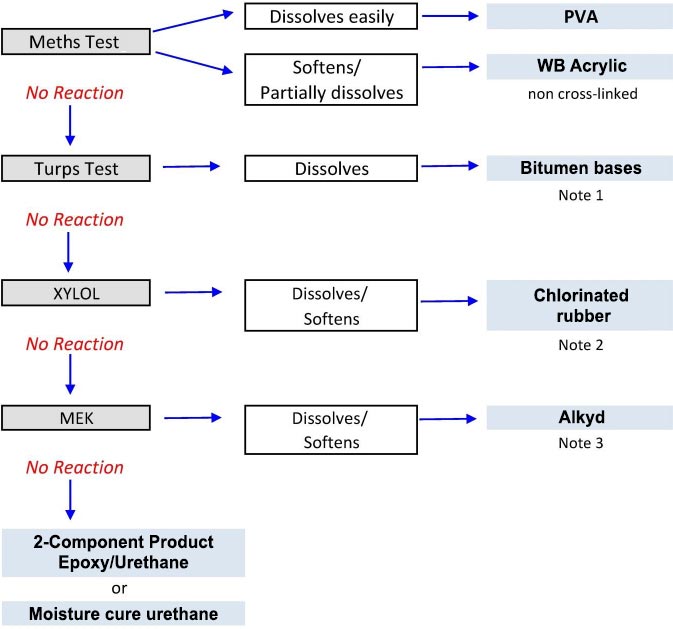

Moisten an area of the test cloth, size of say a 50 cent piece with the test solvent. Hold moistened cloth onto test area for 30 seconds, and then rub. Check cloth to see if paint has been dissolved by solvent. Immediately after removing cloth, rub the test area with your finger to determine if the paint film is soft or sticky.

NOTE: Ensure the rag remains wet at all times with solvent during the test.

Place test rag either in an outside bin or a sealed container for safe disposal later.

Note 1: Solventborne Clear Glaze (F10 Glaze), Cyclised rubber and Pliolite Coatings will also soften and dissolve.

Note 2: Acrylic based coatings are readily dissolved.

Note 3: Vinyls are also soluble and will dissolve. Fully cross-linked (well cured) waterborne enamels e.g. Enamacryl, Lustacryl and SpaceCote may suffer gloss loss and some pigment transfer but generally don’t dissolve.

The degree of reaction not only varies with paint type (resin system) but also gloss level and colour. The higher the gloss level the more resistant the paint may be to the solvents being used. With strong colours (high levels of colorant) there may be a degree of pigment transfer which may make interpretation of softening/dissolution reaction more difficult.

Wear safety glasses and gloves.

Clean test area by using Test 3 procedure – Cleaning Surface. Check for surface chalk using Test 2, if positive then clean until a negative result is achieved.

Using the Sharp Knife and wooden stick as a guide, cut 6 vertical lines approximately 3mm apart, then repeat the same 6 cuts horizontally across the vertical cuts already made (see below diagram).

Place adhesion test tape over the grid area and rub down with curved blunt end of knife or stick. Leave the tape fixed to the surface for 90 seconds and then pull off at a consistent medium speed at a 45° angle.

Poor adhesion of the paint system or layers within it is seen when there is heavy paint removal along the edges of the cuts or when squares have been detached.

Attempt to establish the failure point i.e. If the substrate is exposed then failure is at the base of the paint system (substrate adhesion failure) and the recommendation would call for total removal back to bare substrate before painting.

If a failure within the paint layer (inter-coat adhesion failure), then where, i.e. at what colour is exposed and what colour is on the back of the removed paint?

A measure of the extent of failure can be calculated using the following equation:

| % area of failure | = | Number* of flaked squares | x | 100 |

| 25 | 1 |

* each square = 4% of the total surface area so 1/2 a flaked square = 0.5

e.g. In the above example you have 4 Squares failed, but you also have edge damage to 4 additional squares, with say 0.25 (1%) each and you also have one square with half missing so say 0.5 (2%)

... so 4 x 4 = 16% area + 4 x 1 = 4% area + 1 x 2 = 2% area = 22% area failure

... or using the equation 4 squares + 4 x 1/4 squares + 1/2 square =

5 1/2 x 100 / 25 = 22 so a adhesion failure of 22% of the area

Note: Take a photo of the adhesion test to keep for your records or to use when consulting others for a second opinion.

Sweep test area to remove all loose surface contaminant/dirt and ensure a clear surface.

Lay the sheet down and then seal the edges to the floor by using the tape. Ensure a good seal and then leave for at least 16 hours before then checking on the underside of the plastic sheet for moisture/water droplets or misting.

If no moisture present after 16 hours then proceed with floor preparation and painting.

If moisture is present, then allow more time for the concrete slab to dry out, then repeat test.

Note: Optimally new concrete slabs should be left for at least 30 days to cure and start to “dry out” before painting.

Refer to the CONCRETE BASICS – A Guide to Concrete Practice booklet for more information.

If the water is immediately absorbed and the concrete darkens then there is no curing membrane present.

If not then preparation by diamond grinding must be undertaken to remove the membrane. Grinding must achieve a uniform surface texture similar to 180 grit sandpaper.

June 2018

Disclaimer

The information contained in this printed media is not a specification, has been given in good faith and is to be used as a guide only. It is designed to be used to help offer simple guidelines to help identify potential issues and offer some resolution or solution to a particular problem. Since conditions of use of this publication is beyond the control of the writer, information herein is without warranty, implied or otherwise, and final determination of the suitability of any information or material for the use contemplated, the manner of use is the sole responsibility of the user. This is not a definitive book or specification and must not be used so.

For technical assistance please use our Ask a Paint Expert Service.

Resene Paint and Decorating Problem Solver

Learn more about typical painting problems and situations you may find when decorating.