PaintCrete is a new technology pioneered through a collaborative effort by Firth Industries, 3R Group and Resene. It makes use of waste waterborne paint collected through the Resene PaintWise service.

Resene takes its product stewardship for paint very seriously; some recycled paint is diverted to normal paint uses, such as graffiti obliteration, but what to do with the bulk of the returned waterborne paint that is not suitable for such ‘second use’ was a problem that Resene and 3R were grappling with when they approached Golden Bay Cement in 2005.

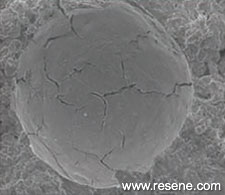

Cement paste air bubble at 2500x magnification.

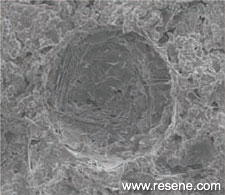

Cement and paint paste air bubble at 2500x magnification.

Golden Bay was aware that latex or acrylic polymers have been key ingredients in high priced mortars and cement grouts for many years. The only barrier to their wider use in concrete had been their high price, and their requirement to be used with de-foaming chemicals.

Waste paint solved both the cost issue and the foaming – control of foaming is an essential requirement of paint and diverting the paint from landfill was a very cost effective, long-term solution. The only questions were how to prove the benefits of PaintCrete to an industry as focused on quality as the ready-mixed concrete producers need to be and how to satisfy design professionals and building consent authorities, in this post-leaky homes era with its distrust of anything new.

The answer was to form the PaintCrete Partnership, a formal relationship between Fletcher Concrete and Infrastructure, Resene and 3R Group; to prioritise those applications where waste waterborne paints could provide added benefits to concrete and to apply for research funding to prove those benefits.

Because of the question of the final colour of the concrete, the first and obvious application was to incorporate it into blockfill for reinforced concrete masonry.

The advantages there were obvious:

The recycled content of the blockfill could be boosted to meet Green Star NZ rating criteria.

The fluid properties of the blockfill would be enhanced to ensure better filling, eliminate the need for revibration and improve the pumpability through small diameter hoses.

The hardened properties were also likely to be enhanced with less shrinkage, better bond between the block shell and the fill and enhanced bond to the reinforcing bars.

To prove these benefits the PaintCrete Partnership approached Associate Professional Jason Ingham, at Auckland University’s Department of Civil and Environmental Engineering. Dr Ingham has a long-established reputation for leading high quality reinforced masonry research in New Zealand and has been actively involved in the production of masonry standards for many years. Jason Ingham also has ready access to New Zealand’s brightest and most motivated Civil Engineering undergraduates, and had enough passion for the topic to make masonry grout sound like an exciting topic to Christopher Haigh.

Trial wall one prior to filling.

Pumping PaintCrete into trial wall one.

Pumping PaintCrete into trial wall two.

PaintCrete after being levelled off at the top surface of the wall.

This North Shore skateboard park is no match for Resene grey recycled EchoPaint.

Nick Nightingale, Resene Managing Director at the nationwide launch of Resene PaintWise.

Resene grey recycled EchoPaint.

A can before and after Resene PaintWise processing. Photo: courtesy of Simon Edwards, Hutt News

Chris initially struggled to find a socially acceptable description for his research topic for party conversations, but came to realise that ‘Saving our planet for future generations’, the lofty goal of the PaintCrete Partnership, was a very adequate description of his research project too. The Master of Engineering topic broadened in scope and scientific rigour as the series of tests to prove the engineering properties evolved, and as the observed behaviour of this new concrete had to be quantified and explained.

Chris was able to draw on the expert advice of some of New Zealand’s most experienced paint chemists and cement scientists; and to be able to use the advanced electron microscope at Auckland University and Canterbury University’s concrete rheometer. These vital pieces of equipment were used to probe the inner workings of PaintCrete both in its fluid state and when it had hardened. Chris also excelled at the time-consuming tasks of coordination of field trials, collecting facts and opinions from the people using PaintCrete and later replicating those conditions in the University concrete laboratory. The fact that Christopher Haigh was awarded the rare distinction of First Class Honours for his Master’s Degree is testimony to both his dedication to the topic and to the new knowledge encapsulated in his PaintCrete work.

PaintCrete is now available from a selected number of Firth readymix plants; the search for other added-value uses of waste paint in concrete continues, but currently the blockfill market neatly matches the volume of available waterborne waste paint at the optimum dose rate.

For those who want to specify PaintCrete or to develop other suitable applications, the addition of randomly mixed, waterborne acrylic and latex paint to concrete, at the prescribed dose rates allows the cement content to be reduced, lowering both the carbon footprint and the embodied energy of the concrete. It makes a very user-friendly concrete that is easier to place and finish and most importantly it does not noticeably affect the final colour. A curious fact, true the world over, is that the random mix of leftover paint (from a large enough market) typically results in a light, concrete grey colour. Talk to Firth about other application for PaintCrete.

For 3R, who are acknowledged specialists in product stewardship, this kind of collaboration shows what is possible when businesses from different industries are prepared to pool their talents, think outside the box and get stuck in. 3R’s role in PaintCrete is to generate ideas, manage the PaintCrete projects and ‘keep it flowing’.

The Resene PaintWise service was conceived by Resene in 1999 and first trialled in 2004. It has been progressively rolled out since 2005 with the assistance of 3R Group and currently most New Zealand Resene owned ColorShops accept paint and paint packaging returns.

The Resene PaintWise service was conceived by Resene in 1999 and first trialled in 2004. It has been progressively rolled out since 2005 with the assistance of 3R Group and currently most New Zealand Resene owned ColorShops accept paint and paint packaging returns.

In the two years to end of 2008, over 300,000 packs were collected from Resene ColorShops and over 100,000kg from council depots. Of this, over 120,000kg of steel was recycled, over 80,000 litres of solventborne paint was sent to solvent recovery so the solvents could be reused and over 60,000 litres of waterborne paint was donated to community groups, much of which was used to cover graffiti.

Celebrating its innovative approach to product stewardship and paint and paint packaging recovery, Resene PaintWise was awarded a Green Ribbon Award in 2008 for innovation, the Business Environmental Leadership Award in the ARC Environmental Awards 2005 and an Award for Excellence in the Environmental Packaging Awards 2005.

Information supplied thanks to Golden Bay Cement, 3R Group and Resene.

› Download a PDF of this article. You will need Acrobat Reader.