From BlackWhite magazine - issue 04, spectrum science

Learn how colour and contrast affect both the look and integrity of your exterior materials.

When you have a specific look in mind for the exterior of your project, it can be extremely beneficial to research the products you’re planning to specify before you or your client get too attached to the idea – especially if you’ve envisaged it to come to life in a very dark hue. Simply put, not every type of exterior material can accommodate mid to dark coating colours. If too deep of a hue gets used, your selection may cause irreparable damage to the substrate, such as warping, checking and premature failure.

While you should always check with your cladding supplier as early on in your project as possible to ensure your colour choices fit within their guidelines, it can also help to understand the science behind a key colour metric and the heat reflective Resene paint products that have been designed specifically to expand your options.

On the back of your Resene colour chart or fandeck and on the Resene online swatch library, you’ll find each hue’s approximate light reflectance value (LRV). Resene keeps master standards of every paint colour in temperature controlled storage so that their quality isn’t degraded by temperature or UV light, and these serve as Resene’s master colour standards. To determine the LRV of each colour standard, Resene uses a spectrophotometer. The measurement it relays is the CIE Tristimulus Y value, which is a fancy way of referring to the brightness of the colour. This, in turn, is used to calculate the LRV.

The LRV of a colour indicates the amount of visible light that the colour will reflect, which is expressed as a percentage. True black body absorber has a light reflectance value of 0%, as it absorbs all light as well as the rest of the electromagnetic spectrum. Consequently, such black surfaces are very dark and can get very hot, because at the same time those surfaces are absorbing that light, they are also absorbing the rest of the sun’s energy. Pure white, on the other hand, has a light reflectance value of 100% and keeps a building light and cool. All other colours fall somewhere between these two extremes.

Given that it’s one of the four key basic design principles, ensuring your project has enough visual contrast is important to its overall impact, and the colours you choose for it play an important role in getting the right effect. Dark colours are popular choices for buildings given that they will often contrast sharply with the surroundings and are also a desirable colour choice for those who want their buildings to look cutting edge. So, what’s a trend-loving specifier to do?

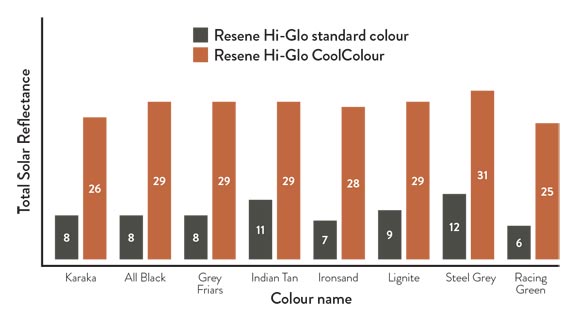

Though you’ll still need to do your research into your specific exterior materials, you may also be able to leverage heat reflective coating technology Resene has pioneered to increase the Total Solar Reflectance (TSR) properties of popular mid to dark colour choices.

did you know? LRV measures only what a colour physically looks like, so a CoolColour and a standard colour will have the same LRV as they both look the same. What changes is the TSR. The TSR gives you insight into how the colour combats the sun – a CoolColour will have a higher TSR (reflect more of the sun) than a standard colour.

Sunlight energy (also known as the electromagnetic spectrum) is made up of 44% visible light, 5% ultraviolet light and 51% infrared light – and each has a different effect on coatings. Visible light is only part of the story.

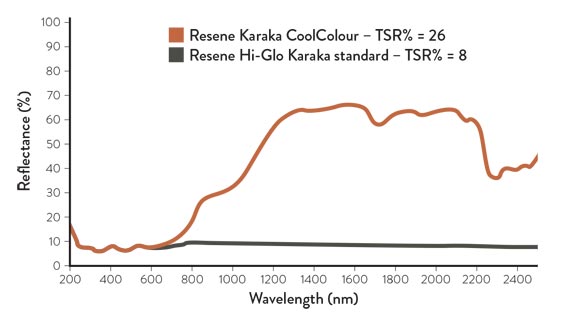

Traditionally, LRV has been used to estimate what colours are suitable for heat prone substrates, however visible light reflectance values only measure a proportion of the energy and ignore the effects of ultraviolet and infrared light. TSR values take into account all three forms of light to give a better measure of the reflectance of the colour. A Resene CoolColour uses pigments that reflect more of the sun’s energy, resulting in the same visible LRV as the standard colour but a considerably higher TSR value.

Over many decades, the ceramics industry has led the charge in developing inorganic pigments which can withstand the ferocious firing cycles of their colours. They developed expertise in creating mixed metal oxides for their purposes. Not only did these pigments perform exceptionally well under UV light but some of them also showed IR reflectivity. These findings were refined to maximise their properties for use in commercial coating applications.

Resene chemists looked initially at Resene Karaka, a popular roofing colour. They incorporated these infrared reflecting pigments and compared the new blend against standard coatings. Over a five minute standard test, the new formula showed a 12℃ lower temperature than the standard colour – which can make a tremendous difference to the stresses exerted on the substrate and has a telling effect on its stability and heat gain.

A similar effect to that which Resene CoolColour technology relies on can also be observed in plants. Most plants have leaves of a very high chroma green. If those leaves reached the same temperature when exposed to solar radiation as a similarly colour paint, they would shrivel and die. The fact that they don’t is partly because their pigment, chlorophyll, absorbs what it needs from the visible range in order to photosynthesise but reflects the infrared range, keeping the plant cool.

Did you know?

Understanding LRV can help you to choose more visually effective colour pairings, too. If you're not sure if two colour choices have enough contrast between them, check their LRV values. While there are outliers to this rule, a general guideline is to ensure there is at least a 30% difference between the two values for there to be obvious contrast. For example, Resene Eighth Tapa has an LRV of 54% and Resene Double Tapa has an LRV of 21%; therefore, the contrast between the two hues will be clearly visible under a range of lighting conditions both inside and out. It's worth noting that LRV values are only available for solid colours. Semi-transparent stains like Resene Woodsman don't have LRV values because the surface is visible through the coating. A LRV value can be determined on a specific sample but it won't be representative of what the LRV would be when different timbers are coated.

When you don’t want to choose between style and the integrity of your substrate, there are savvy paint or wood stain options that could fill your needs. Resene CoolColour paints and wood stains look the same as standard Resene colours but are formulated to reflect more of the sun’s energy and keep your coating, substrate and building cooler. That means Resene CoolColour technology may increase the colour range that’s suitable over certain heat sensitive substrates.

Resene Total Solar Reflectance for Resene Hi-Glo Karaka CoolColour versus standard colour

Total Solar Reflectance for Resene Hi-Glo CoolColour versus standard colours

A quick way to tell if a particular colour is available in a Resene CoolColour formula is to look to the name on your colour chart. You’ll see a ‘cc’ symbol if it can be tinted into a Resene CoolColour. Your Resene representative can also help you determine colour options that will work within the manufacturer’s guidelines for your exterior substrate and the best formulas for your specific job so that your coatings and building materials continue to look great and perform properly.

top tip An easy way to find Resene colours that will work within a manufacturer's specified LRV range is to use the Resene online swatch library. Simply use the dropdown menu to search the colour list to suit your Light Reflectance Value (LRV) requirements.

This is a magazine created for the industry, by the industry and with the industry – and a publication like this is only possible because of New Zealand and Australia's remarkably talented and loyal Resene specifiers and users.

If you have a project finished in Resene paints, wood stains or coatings, whether it is strikingly colourful, beautifully tonal, a haven of natural stained and clear finishes, wonderfully unique or anything in between, we'd love to see it and have the opportunity to showcase it. Submit your projects online or email editor@blackwhitemag.com. You're welcome to share as many projects as you would like, whenever it suits. We look forward to seeing what you've been busy creating.

Earn CPD reading this magazine – If you're a specifier, earn ADNZ or NZRAB CPD points by reading BlackWhite magazine. Once you've read an issue request your CPD points via the CPD portal for ADNZ (for NZ architectural designers) or NZRAB (for NZ architects).