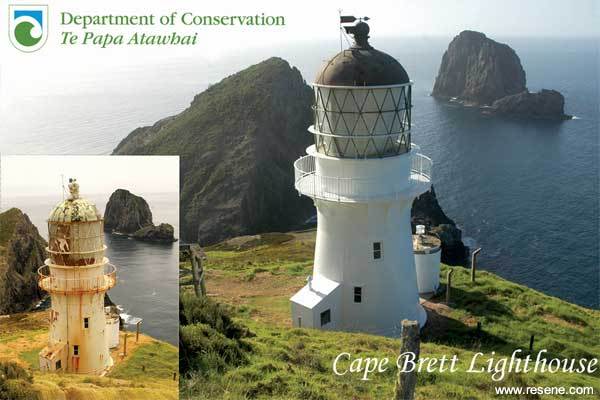

Cape Brett lighthouse

Painting a lighthouse is a challenge in itself, but when it is the iconic 14 metre tall Cape Brett lighthouse attracting international visitors and located on an isolated headland, the challenge is even more daunting.

With isolation comes complicated logistics. Nearly 50 tonnes of equipment was barged out to the Cape to provide materials for the restoration. 12 people plus a Skyworks helicopter and crew helped to transport all the materials, including the four tonnes of granite needed to blast off the paint. The paint was helicoptered from barge to the Cape Brett hut with a 30 metre strop carrying loads of up to 850kg over a period of nearly five hours.

The substantial upgrade of the Cape Brett site being undertaken by DOC includes repairing and repainting the lighthouse and the lighthouse keeper's cottage and tidying up of the general site. The near century old lighthouse exterior was expected to be repainted over a six week period, however around 100 litres of Sea to Sky waterborne paint stripper and an extra fortnight of work was required to strip off the around 60 layers of paint that were found. All scraping was done by hand to minimise the health risks associated with the lead-based paint. The lighthouse was wrapped in green scrim to contain the lead-based paint being stripped off the surface. This resulted in concerned calls with some believing the lighthouse was being painted DOC green. Once the hand scraping was complet the surface was garnet blasted, glass and woodwork replaced and the topcoats applied.

The lighthouse restoration also involved hand refurbishing of the copper dome with ScotchBrite cleaning pads, replacement of the triangular glass windows and doors and the fitting of new stainless steel ladders. Each nearly 300kg door had to be helicoptered off the Cape before the new rosewood replacements could be crafted and transported.

The paint system of Resene ArmourBond, Resene Armourcote 510 and two coats of Resene Uracryl 402 was applied with meticulous care. A weather station was amongst the supplies to provide accurate humidity and dew readings to ensure appropriate conditions for the application and curing of the paint system. The lighthouse had to be washed every day prior to the start of painting necessitating large volumes of water that was also transported in.

Workers remained on site during the project staying at the Cape Brett Hut, the last surviving lighthouse keeper cottage, which DOC now manages as a trampers' hut.

The Cape Brett lighthouse stands at the entrance to the Bay of Islands. In 1906, the Department of Transport identified the entrance to the Bay of Islands as an ideal location for a manned lighthouse to fill the gap between Cape Van Diemen and the Mokohinau Islands, which mark the northern approach to the Waitemata Harbour. The lighthouse utilised innovative technology for the time as the light revolved in a bath of mercury reducing friction, rather than the beveled rollers and ball bearings that were typical at the time. The light emits two successive flashes every 30 seconds visible for up to 26 nautical miles. Manned by three keepers, the settlement consisted of three homes to house the keepers and their families, until it was decommissioned in 1978 and replaced by a small automated light.

In 1984 the bulk of the Cape Brett Reserve was passed to the Department of Lands and Survey, with DOC becoming responsible for administration from 1987.

Visitors to the lighthouse remark that it is like walking back in time with the interior fitted out in extensive brasswork. The lighthouse is, in theory, fully operational and could be turned on with a flick of a switch, though the now antique wiring might struggle to cope.

A key part of New Zealand's coastal history and a feature on thousands of Hole in the Rock trips, the Cape Brett lighthouse is once again shining bright.

Applicator: CW Rudolph and Sons Ltd, Whangarei

Architect: Studio Pacific Architecture, Hamilton

Owner: Department of Conservation

Project Manager: Andrew Blanshard, Historic Ranger

Resene: Stef Christodoulou, Northland Branch Manager

From the Resene News – issue 2/2008

Resene case studies/awards project gallery

View case studies that have used Resene products including many from our Resene Total Colour Awards. We hope these projects provide inspiration for decorating projects of your own...view projects

Total Colour Award winners:

2023 |

2022 |

2021 |

2020 |

2019 |

2018 |

2017 |

2016 |

2015 |

2014 |

2013 |

2012 |

2011 |

2010 |

Entry info

Latest projects | Project archive | Resene news archive | Colour chart archive