From the putting your safety first section

It is not possible to set out precise requirements for every industrial situation where there is an inhalation hazard because the factors that have to be considered vary from one workplace to another. Both the user and the supplier should be satisfied that the equipment selected is adequate for the conditions. If in doubt, you should seek technical advice from your equipment supplier or your local branch of the Occupational Safety and Health Service of the Department of Labour (OSH).

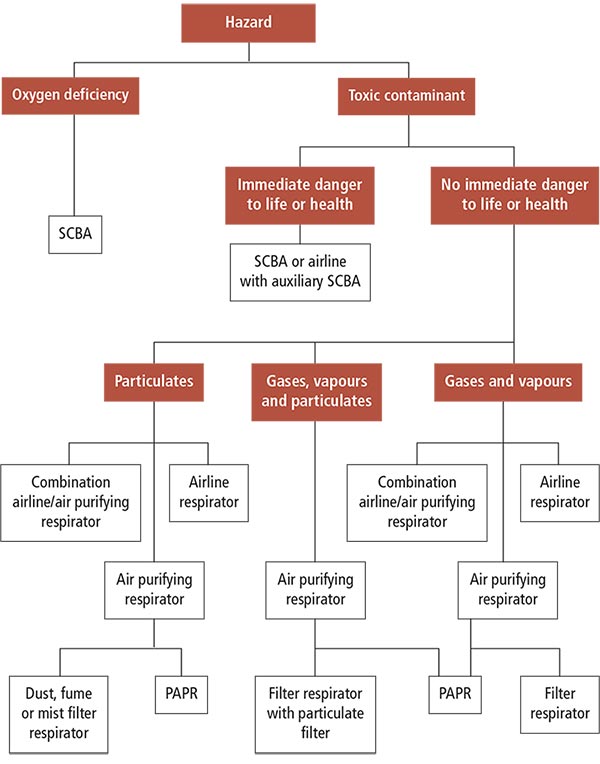

Respirators protect against the following hazards:

Respirator protection is required for different categories of dust:

Nuisance dusts: These may cause discomfort (i.e. cough or phlegm) or minor irritation of the nose and lungs but are usually not toxic and do not permanently damage the lungs. They pass out of the body or remain in the lungs without poisoning the system. Examples are calcium carbonate (limestone dust), starch and sucrose.

Lung-damaging dusts: Respirable particles of these dusts remain in the lungs where they may damage the tissue. For example, asbestos,crystalline silica (quartz dust) and coal dust.

Irritant particles: Chemically active particulates that cause immediate discomfort,irritating or inflaming the airways to the lungs. Examples are acid or alkaline mists and cement dust.

Fever-producing dusts: Dusts that produce flu-like symptoms and fever, sometimes several hours after exposure. For example, fumes evolved from welding zinc or copper.

Toxic dusts: These pass from the lungs into the blood and may poison the whole body. For example, lead, arsenic and powdered organophosphate pesticides.

Sensitising agents: Particulates in low concentration that may cause an allergic reaction. An example is mould.

These are fine droplets of liquid dispersed in the air and may contain particles of dissolved substances. Mists are produced by condensation of a vapour or by atomisation of a liquid. Examples are paint spray and chromic acid mist from an electroplating bath.

These are fine particles of metal, produced by condensation of the vapour, given off by a metal when it is subjected to high temperatures, for example, during welding and smelting.

NOTE: Inhaled particles deposited in the mucus in the respiratory airways will enter the body when swallowed.

There are three categories of gases and vapours for which different types of respiratory protection is required:

Before entering a confined space, it is essential to carry out a full assessment of the likely contaminants and possibility of oxygen deficiency. A decision on the appropriate type of respiratory equipment and other safety factors will then need to be made. For further information, see the booklet ‘Safety in Confined Spaces’, available from your local OSH branch office.

Three main factors need to be considered when selecting a suitable respirator for a particular situation They are:

If you have any doubts as to the correct device for a particular situation, you should seek expert advice from the equipment supplier, your OSH branch office or other authority on occupational hygiene.

There are some medical factors that may preclude or limit the use of respirators:

PAPR = powered air purifying respirator

SCBA = self-contained breathing apparatus

For further information refer to 'A Guide to Respirators and Breathing Apparatus' published by the Occupational Safety and Health Service of the Department of Labour, Wellington.

Putting your safety first!

Understanding paint hazards and essential precautions